As an ophthalmologist overseeing the setup of a modular OT for a trust hospital, I had the unique chance to get involved in the real nuts and bolts of the process. This write-up shares my on-ground experience—what worked, what didn’t, and the small but important details that can make a big difference. It includes actual vendor quotes and comparisons from two different suppliers for a 15×15 ft setup, along with firsthand experience with the choice we ultimately made. This blog is meant for the solo eye surgeon or private practitioner who wants to understand the process clearly before committing to it. It doesn’t claim to follow textbook facts—but in areas like sterilisation- an incomplete science where definitive answers are rare, shared experience often becomes as important textbook dogma. The final infrastructure and processes were vetted thrice by DBCS officials before we were cleared to begin surgeries. Any opinions, suggestions, and shared experiences from others who’ve been through similar setups are most welcome.

— Dr. Shantanu Gulati

MODULAR YOU SAY ?

A Modular Operation Theatre is a pre-fabricated, controlled-environment OT setup designed with seamless, non-porous surfaces (walls, ceiling, and flooring), dedicated Air Handling Units (AHUs) with HEPA filters, positive pressure, and zoned airflow to maintain Class 1000 (ISO 6) air quality.

So basically a modular OT in currently understood terms entails

- Pre fabricated seamless non porous surfaces

- Air Handling Unit (ASHRAE standards)

First things first – “DOES NABH REQUIRE MODULAR OT ?”

Well, yes and no.

- PRE FABRICATED WALLS / “MODULARITY”

- The 2018 “Revised guidelines for air conditioning in operation theatres” (NABH – 2018) clearly mention “Modular Operation Theatre is NOT A MANDATORY REQUIREMENT under any program. It is totally left to HCO whether they want to install it.”

- The flooring, walls and ceiling should be non porous, smooth, seamless without corners and should be easily cleanable repeatedly. The material should be chosen accordingly. – “Guide Book to NABH Standards for Hospitals” – Amendment – August 25,2010

- AIR HANDLING UNIT –

- AHUs have been made mandatory for all types of Ots in hospitals applying for NABH- Revised guidelines for air conditioning in operation theatres” (NABH – 2018)

BUT

This does not hold true for those applying for “pre accreditation” As stated in the same revised guidelines – “Though these guidelines are desirable under all programs, they are NOT MANDATORY for the SHCOs and HCOs implementing pre-entry certification standards.”

So with the two most common queries out of the way, lets start with the basic building blocks of a modular OT, and to make things easier to understand we’ll have you glance over these two detailes quotes / bill of materials from 2 different vendors –

1. Seamless, Non-Porous Wall Panels

When it comes to operation theatre walls, multiple options exist in both prefabricated panel systems and traditional seamless vitrified tile installations.

Among prefabricated options most commonly offered are PUF sandwich panels (polyurethane foam core between two outer layers), with outer materials such as:

- Stainless Steel (SS304) panels

- Powder-coated GI (Galvanised Iron)

- High Pressure Laminate (HPL)

- Epoxy Gelcoat Panels (EGP)

The claim with these panels are

- Being prefabricated they are easy to install and faster to replace (Modular)

- Usually come in sizes of desired height and 4 feet width, so seams are lesser compared to tiling

- The PUF sandwich provides sound and temperature installation

- The surfaces are usually treated and graded for anti microbial properties

Since we took detailed quotes regarding HPL and EGP, and gathered some info regarding SS, the same is mentioned in a tabular format below. There are other materials too with some pros and cons over these as per vendors but the gist remains the same.

| Feature | SS304 Panels | HPL Panels | EGP Panels |

| Approx. Cost (per sq. ft.) | Most expensive | ₹475 | ₹300 |

| Glare Issue | Yes – glare under light | No | No |

| Seam Handling | Can be butt welded for seamless joints | Silicone filling between pre-painted panels | Panels are installed, plastered, silicone filled, then painted with antimicrobial coating |

| Vendor provided data | Not procured | 44mm | HPL 4mm on room side | PUF 43kg/m3 | 50mm | EGP0.8mm inside and 0.5mm outside | Silicone + Epoxy flush + paint | PUF 40kg/m3 |

So how did we choose?

| What we looked at | Why it mattered (and still does if you’re deciding now) |

|---|---|

| Certifications | ISO 14644-1 Class 6 compliance had to be on paper, not in conversation as per DBCS. Any vendor who couldn’t show it was ruled out immediately. |

| Cost | Stainless steel sat at the top of the price ladder, with HPL next and EGP the least expensive. We weighed each quote against expected longevity and performance, not just the upfront number. |

| Practical quirks | Even a matte SS sheet can bounce OT lights back at the surgeon. We noted that SS joints could be butt-welded for a truly seamless finish, whereas HPL and EGP would need silicone at every 4-ft joint. |

| Vendor relationship & serviceability | Service relationship mattered more than specs. We chose the vendor we knew would show up if something went wrong. |

Where we finally landed

We had two shortlisted vendors:

- Vendor A championed EGP.

- Vendor B pushed HPL as the sensible middle path.

Both gave credible technical arguments, but service history tipped the scales. The trust already had a reliable five-year track record with Vendor B, so—despite HPL’s higher price—it felt like a safer long-term bet.

Our Experience with HPL Panels

| Promise | Reality |

| Certification | ✅ Provided |

| Modularity | ✅ Present |

| Seamlessness | ❌ Poor — silicone joints aren’t truly seamless |

| Install-and-forget | ❌ No — maintenance issues began early |

| Finish quality | ❌ Far from flawless |

The HPL cladding gave the theatre a sleek, modern look with fewer visible seams compared to traditional options like vitrified tiles. The panels were initially questioned by DBCS officials for appearing like wooden laminates, but the certification provided by vendor addressed the concern and settled the issue without further objection.

However, our experience highlighted a few important realities that often don’t show up in brochures:

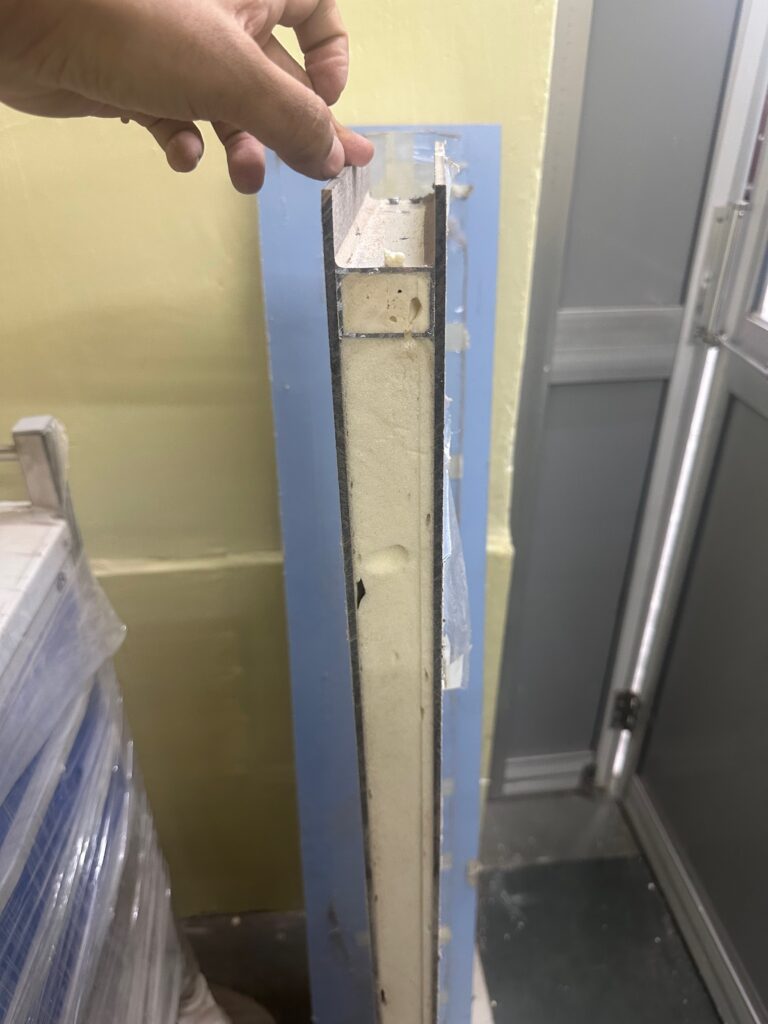

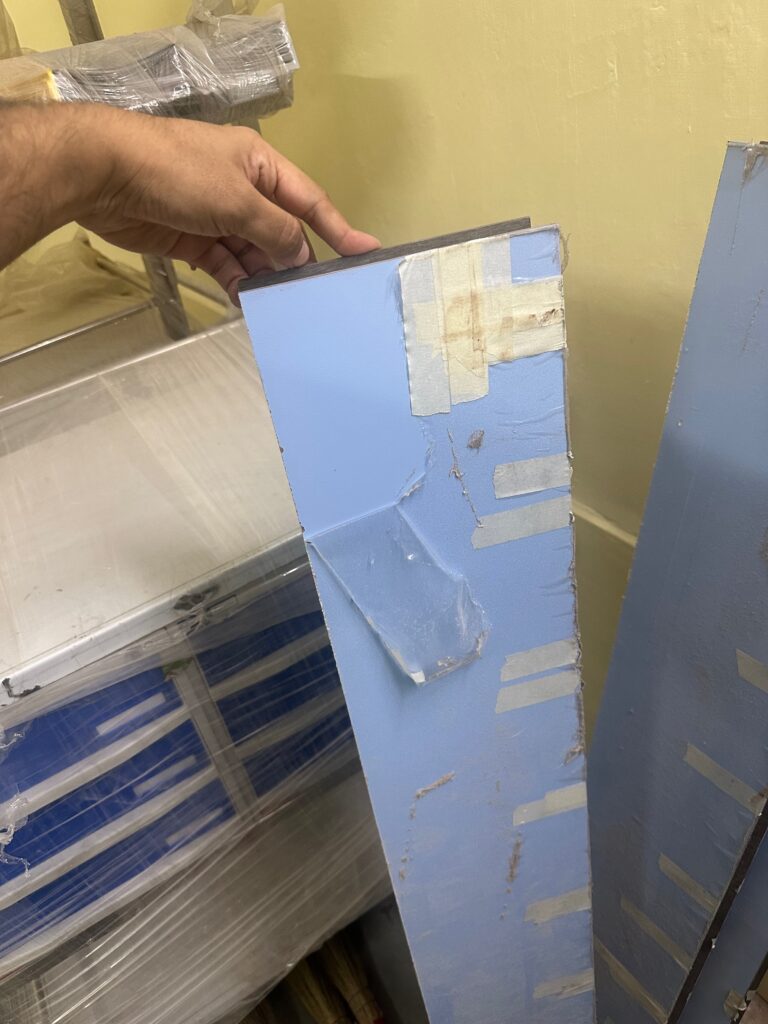

- Coving details can be counterproductive – The aluminium channels used to form coves actually introduced right-angled crevices—undermining the very goal of cleanability and microbial resistance.

- Seamless” still needs skill – While the panels are modular, achieving a clean, uninterrupted finish relies heavily on precise on-site cutting, sizing, and silicone finishing. In practice, the installation requires lesser civil work than conventional options but a “motivated” skilled labour is a must.

- Delamination is possible – Within three months, we observed delamination in parts of the HPL surface. The vendor suggested a possible roof leak—despite there being no visible signs of water ingress. We proceeded with roof waterproofing purely out of caution. While a free panel replacement has been promised, it remains pending.

Youtube links to final look of the OT here-

What about conventional options?

Conventional options include

1. Walls with punning and antimicrobial paint – degrade with repeated cleaning, cracks in paint

2. Vitrified tiles with epoxy grouting

So as previously mentioned NABH does not mandate prefabricated or modular wall systems. The actual requirement is for “seamless, non-porous, easily cleanable” finishes, which can be also e achieved with vitrified tiles, provided installation is done thoughtfully with minimal joints and good waterproof, chemical resitant epoxy grouting.

In fact, many doctors with NABH-accredited hospitals continue to use vitrified tiles and vouch for them. One such respected surgeon I came across is Dr. M.S. Ravindra sir of Karthik Netralaya, Bengaluru. There are beautiful videos on youtube showcasing his NABH accredited OT and I personally confirmed with him at AIOC 2025 that he is still using vitrified tiles without any NABH troubles.

Watch the video below : –

🧾 Quick Comparison: HPL Panels vs Vitrified Tiles

Comparison: HPL Panels vs. Vitrified Tiles

| Feature | HPL Panels | Vitrified Tiles |

| Appearance | Sleek, uniform, modern | Clean but grouted; less “modular” look |

| Seams | Fewer, but still need silicone sealing | More joints; visible grouting |

| Cleanability | Good if properly sealed | Good if grouting is minimal and well maintained |

| Maintenance | May delaminate if moisture seeps in | May crack, but individual tiles are easy to replace |

| Cost (approx.) | ₹450 per sq. ft. | ₹150 per sq. ft. |

| NABH Compliant? | Yes | Yes (if smooth and well-installed) |

| Installation | Needs trained team and precise panel sizing | Local tile mason can execute with proper care |

So what should I choose?

In summary, PUF panels—whether HPL, epoxy-coated, or powder-coated GI—are often presented as essential for a modern OT. In reality, they are neither mandatory nor without drawbacks.

The right choice depends on your local context such as availability of trusted local mason team or a modular OT vendor in the same city.

Ultimately, whether the extra cost of pre fabricated panels is worth it depends less on proven safety advantages and more on how much value you place on:

- Aesthetic appeal

- Seamless, uniform finishes

- And perceived “premium” branding of your OT

This completes our “Wall panels section” of modular OT. Any new data received from our trusted ophthalmolgist community will be added in continuity with references.

Stay tuned for the next upcoming section – Modular OT Flooring.